다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

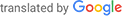

- 2. 견적 거래 절차 안내

Qinchuan Machine &Machine Tool Group

CNC 웜기어 연마기/연삭기 - CNC worm gear grinding machine YK7240

견적거래 제품

영어/중국어만 지원하고 있습니다.

- diameter : Φ20~Φ300(Φ400)mm

- max. workpiece : 5-600

- max. external teeth : 1-6mm

- 연마규격 : Φ300*Φ160*125

- 연마속도 : 2200-4000rpm

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

Qinchuan Machine 제조사

문의전화 : 010-3375-5684 제조사 ‘Qinchuan Machine &Machine Tool Group’ 에서 직접 판매하는 제품입니다.

Qinchuan Machine &Machine Tool

CNC 웜기어 연마기/연삭기 - CNC worm gear grinding machine YK7240

제품정보

Machine Overview: YK7240 CNC worm wheel grinding machine is a new structure of funny high-precision gear grinding machine, with 11 axis five linkage function. The machine tool seeks to upgrade the machine's overall performance to a new level through a new structural layout, advanced drive technology and drive technology, complete with automatic tool setting technology, automatic loading and unloading technology, and high-speed grinding technology. Greatly improve the grinding efficiency of the machine tool.

High-efficiency grinding: The use of a multi-head worm wheel with a linear speed of 63m/s and a continuous displacement grinding function enables quick grinding of workpieces with a large feed rate and doubles the grinding efficiency.

Fully automatic control: Using the multi-channel control platform provided by the SIEMNS 840D control system, eleven CNC axes can be flexibly controlled, and the entire process from automatic workpiece setting, automatic tool setting, automatic grinding to automatic dressing of the grinding wheel can be realized. Control, in the true sense of unmanned operation.

A variety of grinding options: The machine has a manual grinding method, automatic manual grinding and automatic grinding options. In the manual grinding mode, manual clamping can be performed to clamp and loosen the workpiece chuck and terminate the grinding wheel feed. It can be used for single-gear grinding. The automatic grinding method is used for grinding of bulk gears.

High-precision grinding: The use of advanced direct drive technology and software electronic gearbox (EG) technology enables precise dressing of grinding wheels and high-precision grinding of workpieces.

Tooth shape, tooth to practice: Tooth profile can be made into special diamond roller according to user requirements; Tooth profile can be processed through the CNC control column radial feed axis and the slide axial feed axis, processed into the desired shape .

Cooling nozzle position is automatically adjusted: It can ensure that the coolant enters the grinding zone accurately as the diameter of the grinding wheel changes, which is beneficial to improve the quality of the grinding surface.

Automatic loading and unloading: The workpiece can be automatically clamped by two parallel mechanical clamps, which reduces the operating strength of the machine and saves the auxiliary time (this function is an optional configuration).

Automatic knife setting: It can realize the automatic centering of the workpiece tooth slot and the automatic distribution of the remaining capacity, which simplifies the operation of the machine tool and improves the processing efficiency.

Machine specifications:

Processing outside diameter: Φ20~Φ300(Φ400)mm

Workpiece teeth: 5-600

Workpiece module: 1-6mm

Maximum tooth width: 300mm

Maximum helix angle: ±45°

Column radial stroke (X1 axis) 400mm

Traveling tangential stroke (Y1 axis) 220mm

Axial travel of the slide (Z1 axis) 430mm

Workpiece spindle end face and tailstock tip distance 230-870mm

Grinding wheel spindle power 15.5KW

Grinding wheel speed grinding 2200-4000rpm dressing 45-90rpm

Grinding wheel specifications Φ300*Φ160*125

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

010-3375-5684