다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

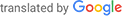

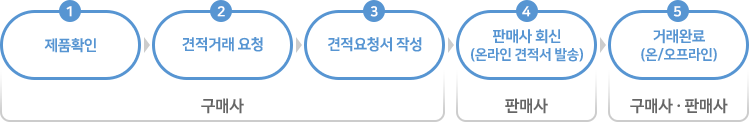

- 2. 견적 거래 절차 안내

㈜에사코리아

자기열교환형 버너 ESA ESTRO

견적거래 제품

견적거래

- ESA ESTRO - E7014

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

에사코리아 제조사

문의전화 : 0504-3175-2678 제조사 ‘㈜에사코리아’ 에서 직접 판매하는 제품입니다.

브랜드소개

제품정보

ESA ESTRO는 공업용 버너의 점화, 감시용으로 입출구에 부착되는 화염조절용 마이크로프로세서로, 총 4가지 버전으로 제공됩니다.

- Estro-A 1단계식 버너용(에어&가스밸브)기기 일반 점화중인 버너의 전자 신호(시그널)형 원거리 수동조절 또는 순차적 조절용입니다.

- Estro-B 2단계식 버너용(pilot와 메인가스벨브)기기, 강력점화중인 버너의 전자 신호(시그널)형 원거리 수동조절 또는 순차적 조절용입니댜.

- Estro-C 1단계식 버너용(단독 가스밸브) 기기, 일반 점화중인 버너의 전자 신호(시그널)형 원거리 수동조절 또는 순차적 조절용입니다.

- Estro-Q 1단계식 버너용(단독 가스밸브)기기, 원거리 순차적 조절용입니다. 모든 버전의 기기에는 에어 셔터, 송풍기, 압력스위치가 설치된 버너의 조절을 위하여 EXP-1 시리즈의 확장카드를 적용시킬 수 있습니다.

ESA ESTRO is a microprocessor operated device, designed

to control gas and oil fired burners, which are

discontinuously operated. This device warrants the safe

operation of the combustion unit at one or two stages

(pilot/main burners), it controls the air flow rate and

allows the detection of flame presence through ionization

(electrodes) or UV radiation (UV-scan). ESA ESTRO is

equipped for serial communication, allowing a remote

burner control and operation. The thermal resistant case

of ESA ESTRO allows its installation on burner proximity,

provided that the environment temperature remains

below 60°C.

APPLICATIONS

One or two stage (pilot/main) discontinuous burners.

Flame detection by means of rod, unirod and UV scan (also combined).

Packaged burners managing a complete ignition cycle (blower, air damper, air pressure switch).

Burners with air valve control for furnace purging, burner ignition and thermoregulation (heating/cooling) via external regulation device.

Combustion plant with burner controller via digital signal or ECS serial communication.

Customized burner operation through programmable expansion cards.

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

0504-3175-2678