다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

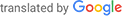

- 2. 견적 거래 절차 안내

CREATOR PRECISION CO LTD

Plastic injection molding machine 플라스틱 사출성형기 - CNC-200

견적거래 제품

통/번역 서비스는 다아라몰(1588-0914)로 문의바랍니다.

- SCREW STROKE : 125 mm

- SCREW SPEED : 0 ~ 240 rpm

- NOZZLE STROKE 280 mm

- NOZZLE FORCE : 3.5 (34) mm tonf (kn)

- NOZZLE DISTANCE : 330 mm

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

CREATOR PRECISION 제조사

문의전화 : 8860423376000 제조사 ‘CREATOR PRECISION CO LTD’ 에서 직접 판매하는 제품입니다.

CREATOR PRECISION CO LTD

Plastic injection molding machine 플라스틱 사출성형기 - CNC-200

브랜드소개

제품정보

/ CD-200

SPECIFICATIONS

| Item | Unit | Model : CD-200 ( F ) | Model : CD-200 ( R ) | ||||

|---|---|---|---|---|---|---|---|

| INJECTION UNIT► | |||||||

| SCREM DIA. | mm | 32 | 36 | 40 | 32 | 36 | 40 |

| INJ. VOLUME | cm3 / shot | 101 | 127 | 157 | 101 | 127 | 157 |

| INJ. CAPACITY | g / shot (ps) | 96 | 120 | 150 | 96 | 120 | 150 |

| PLASTICIZING RATE | kg / hr (ps) | 28 | 38 | 52 | 28 | 38 | 52 |

| INJ. PRESS | kgf / cm2 | 2390 | 1890 | 1530 | 2390 | 1890 | 1530 |

| INJ. RATE | cm3 / sec | 127 | 160 | 198 | 127 | 160 | 198 |

| SCREW STROKE | mm | 125 | |||||

| SCREW SPEED | rpm | 0 ~ 240 | |||||

| NOZZLE STROKE | mm | 280 | |||||

| NOZZLE FORCE | mm tonf (kn) | 3.5 (34) | |||||

| NOZZLE DISTANCE | mm | 330 | |||||

| CLAMPING UNIT► | |||||||

| CLAMP FORCE | tonf (kn) | 200 (1960) | |||||

| CLAMP STROKE | mm | 500 | |||||

| MIN. THICKNESS | mm | 200 | |||||

| DAYLLGHT OPEN | mm | 700 | |||||

| TIE BAR DISTANCE | mm | 530 x 530 (784) | |||||

| PLATEN SIZE | mm | 780 x 780 (720) | |||||

| EJECTOR STROKE | mm | 142 ( X / L ~ 75mm ) | |||||

| EJECTOR FORCE | tonf (kn) | 4 (39) * 2 piece | |||||

| OPENING MOLD FORCE | tonf (kn) | 9 (88) | |||||

| OTHER► | |||||||

| MAX.SYS.PRESS | kgf / cm2 | 175 | |||||

| MOTOR POWER | kw (hp) / pole | 30 (40) / 6 | |||||

| HEATER CAPACITY | kw | 7.4 + 7.4 = 14.8 | |||||

| HYD.OIL REQ. | Liter | 580 | |||||

| MACHINE SIZE | (L x W x H) M | 5.7 x 1.5 x 1.95 | |||||

| FLOOR SPACE | M | 4.5 x 1.3 | |||||

| MACHINE WEIGHT | ton | 9 | |||||

FEATURE

/ CD-200

Features:

- Two independent injection unit can reduce the cycle time.

- Hydraulic clamping unit, the mould deformation is very less and the injection moulding is more accuracy.

- Linear transducer for the injection, clamping position control.

- Screw and barrel made by ACM2 material process with nitride for high ware resist.

- Four heating zone controller by PID the accuracy can reach to ±1℃

- Two independent ejector designs for easy operation.

- Advance turntable mechanism design for fast moving and precision positioning.

- Heavy duty turntable (CD-200 nay reach too 1000kg) to ensure the mold do not falling during operation. High precision and speed turntable, the speed can reach to 2 second/180

- Advance Japan made star controller with 10*color LCD screen for easy operation.

Controller

- Programmable "STAR" controller, made in Japan.

- High resalution display screen with various function display.

- SPC parameter is easy to set up & modify.

- Monitor operation procedure.

- Instart display operation & operation time.

- Open, close mode & ejection.

- Production management.

- 4 steps temperature setup, expand to 6 steps.

- Oil temperature display in 1 section.

- Oil prehcat function.

- Thermo control curve.

- 100 SPC recard.

- SPC precision comparison.

- Internal storage of 60 machine setup.

- Display temperature predision scale.

- Pressure curve*, Speedcurve*.

- IC memory card to expandstorage of machines setup*.

Programmable computer unit:

High efficiency and easy-to-use display

10" color screen (option)

- The computer controller, made in Japan with LCD display, is easy to use, operate, andset.

- It is quick and simple to call up the program to the LCD display for modification.

|  |

Injection/charge setting apge | Injection/charge setting apge |

|  |

Machine status page | Temperature setting page |

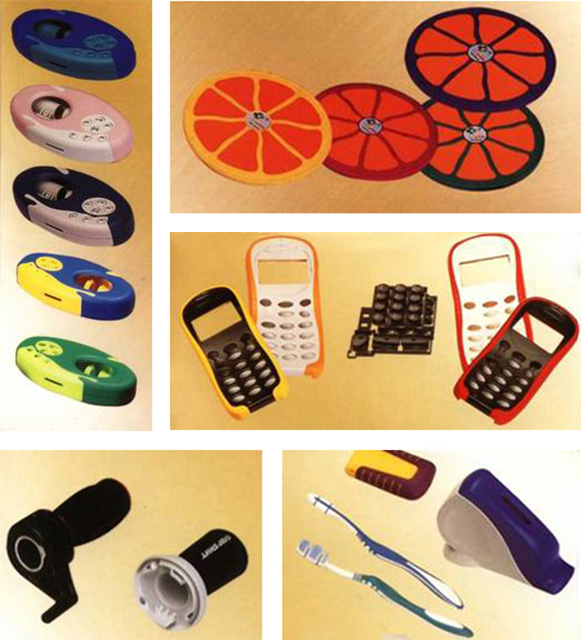

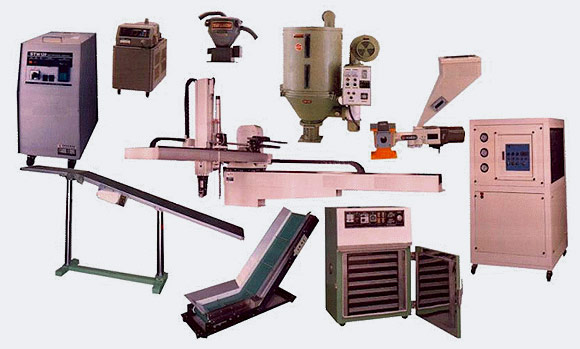

These accessories are available locally and are manufactured to the highest quality.

Please see below for what we can supply.

(Please Note: These accessories are not sold separately, only with a Creator Machine)

- Auto Loaders

- Hopper Dryers

- Dust Collectors

- Robots

- Moulds

- Granulators

- Conveyors

- Chillers

- Dehumidifiers

- Mould Temperature Controllers

- Oven Dryers

- Masterbatch

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

8860423376000