Application:

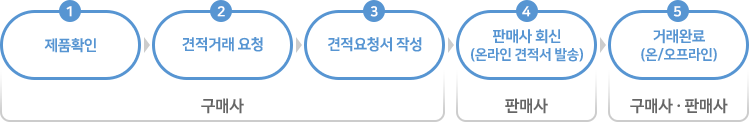

Working procedures:

1. Filling products on vibrator feeder of Z bucket conveyor (incline conveyor) on floor, and it will be lifted on the top of multihead weigher;

2. Multihead weigher will automatic weighing according to preset weight;

3. Preset weight products drop through throat metal detector, if with metal will be rejected out, quality will be packed;

4. Products without metal will be dropped into pre-made bag and sealing;

5. Finished package will be output to check weigher, if over or less weight, it will be rejected, if not, pass to rotary table;

6. Products will get to rotary table, and worker put them into paper box.

Features:

1. Fully-automatically procedures from material feeding, weighing, filling, date-printing, sealing to finished products output;

2. Different weight only need to preset on touch screen of multihead weigher;

3. 8 station holding pouches finger can be adjusted on the screen, convenient for change different bag size;

4. All food contact parts can be took out without tool, easy cleaning after daily work.

Specification:

| Model | SW-PL6 |

Weighing Range

| 10-2000 grams

|

Bag Size

| 120-350mm(L) ; 120-300mm(W)

|

Bag Style

| Stand up pouch, spout, flat

|

| Bag Material | Laminated film; Mono PE film

|

Film Thickness

| 0.04-0.09mm

|

Speed

| 5-40 bags/min

|

Accuracy

| ± 0.1-1.5 grams

|

| Working Station | 8 station |

Control Penal

| 7" or 9.7" Touch Screen |

| Air Consumption | 0.8Mps 0.4m3/min |

| Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System

| Stepper Motor for scale; Servo Motor for bagging

|