다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

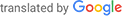

- 2. 견적 거래 절차 안내

AGMACHINE TECHNO CO

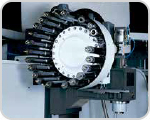

VERTICAL MACHINING CENTER 수직 머시닝센터 VMC-95/115/116

견적거래 제품

대만 본사 직접 판매 '견적문의' 중국어/영어 문의 가능합니다.

- All three axes have a hardened box-way design.

- Oil Circulating Cooling System for Spindle

- Enhanced Base Design

- 24 Tools Magazine

- Automatic Lubrication System

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

AGMA 제조사

문의전화 : 010-3375-5684 제조사 ‘AGMACHINE TECHNO CO’ 에서 직접 판매하는 제품입니다.

AGMACHINE TECHNO CO

VERTICAL MACHINING CENTER 수직 머시닝센터 VMC-95/115/116

브랜드소개

제품정보

VMC-95/115/116

|

| This allows for rapid and efficient chip removal during machining in order to maintain a clean machine. |

| A high efficiency spindle cooling system dissipates running induced heat generation in order to maintain spindle accuracy and prolong spindle life. |

| THE C.T.S. (COOLANT THROUGH SPINDLE) (A TYPE) system provides 20 bar (280 PSI) of hi-pressure coolant delivery that effectively reduces tool wear because of heat and the slow evacuation of metal chips. |

| All of our machines are calibrated according to the "VDI 3441 3δ" standard. Calibration is performed for the full travel length of each axis. Each measurement is taken six times to ensure the most consistent and accurate readings. |

| The base of the VMC-95/116 has 4-hardened ways that allow for greater stability and accuracy even with heavy loading. In essence, the design fully supports the saddle and table along the entire travel lengths of the X and Y-axes. |

| A rapid arm-type tool changer is driven with a precision cam, maintaining toolchanging accuracy of 0.01mm, which in turn will help maintain long-term spindle-clamping accuracy. |

| All AGMA machines use a pressurized central lubricating system. The PLC controlled system allows all three axes to be lubricated evenly to maintain accuracy and prolong machine life. |

| To prevent any deviation between the servomotor housing and ball screw bearing housing, each axis is equipped with two stoppers to guarantee absolute axial alignment. |

| Lubricating oil is evenly distributed to all the sliding surfaces of the machine via volumetric oil distributors. All stationary lines are made of rigid alloy pipe and hard-plumbed for low maintenance operation over the life of the machine. |

| Equipped on the right front side of base this unit along with the assistance of a high-pressure coolant and air mixture helps increase table cleaning speed. |

| Model | VMC-95 | VMC-115 | VMC-116 | ||

|---|---|---|---|---|---|

| Spindle | Spindle Taper | No. 40 | No. 40 | No. 50 | |

| Transmission | Belt Driven | Belt Driven | Gear Driven | ||

| Spindle Speed | 8,000 r.p.m. | 8000rpm | 6000rpm | ||

| Table | Table Size | 1,050 x 580 mm (41.34" x 22.83") | 1,200 x 580 mm (47.24" x 22.83") | 1,200 x 600 mm (47.24" x 23.62") | |

| T-Slot Size | 18 x 5 x 120 mm (0.71" x 5 x 4.72") | ||||

| Work Area | 900 x 550 mm (35.43" x 21.65") | 1,100 x 550 mm (43.31" x 21.65") | 1,100 x 600 mm (43.31" x 23.62") | ||

| Max. Table Load | 800 kgs (1,760 lbs) | ||||

| Travel & Feedrate | X Axis | 900 mm (35.43") | 1,100 mm (43.31") | ||

| Y Axis | 550 mm (21.65") | 600 mm (23.62") | |||

| Z Axis | 580 mm (22.83") | 600 mm (23.62") | |||

| Distance from Spindle Nose to Table | 170~750 mm (6.69"~29.53") | 170~770 mm (6.69"~30.31") | |||

| Distance from Spindle Center to Column Ways | 610 mm (24.02") | 645 mm (25.39") | |||

| Rapid Traverse | X, Y : 20 m/min (787 IPM) Z : 15 m/min (590 IPM) | ||||

| Cutting Feedrate | X, Y, Z : 1~10,000 mm/min (393 IPM) | ||||

| ATC | Tool Shank | BT-40/CAT 40 | BT-50/CAT- 50 | ||

| Pull Stud | MAS P40T-1 (45º) | MAS P50T-1 (45º) | |||

| Magazine Capacity | 16 tool (option) / 24 Tool (standard) | 24 Tool (standard) | |||

| Max. Tool Diameter (with adjacent pocket empty) | Ø125 mm (4.93") | Ø150 mm (5.92") | |||

| Max. Tool Diameter (full storage) | Armless=Ø100 mm (3.94") Arm=Ø80 mm(3.15") (option) | Ø125 mm (4.93") | |||

| Max. Tool Length | 300 mm (11.81") | ||||

| Max. Tool Weight | 7 kgs (15.4 lbs) | 8 kgs (17.6lbs) | |||

| ATC Type | Arm Type (std.) /Armless Type (opt.) | Arm Type (std.) /Armless Type (opt.) | |||

| Motor | Spindle(Cont./30min.) | 7.5/11 kw (10/15 HP) | 11/15 kw (15/20 HP) | ||

| X/Y/Z Axes(Fanuc) | 3/3/3 kw (4/4/4 HP) | 3/3/4 kw (4/4/5.4 HP) | |||

| Lubrication Pump | 0.025 kw (0.033 HP) | ||||

| Coolant Pump | 0.49 kw (0.66 HP) | ||||

| Misc. | Machine Height | 2,767 mm (108.94") | |||

| Floor Space | 3,000 x 2,432 mm (118.11" x 95.75") | ||||

| Machine Weight | 6,700 kgs (14,740 lbs) | 7,000 kgs (15,400 lbs) | 7,300 kgs (16,060 lbs) | 8,000 kgs (15,400 lbs) | |

| Control | Fanuc 0iMF | ||||

| Positioning Accuracy (Full Travel) | ±0.005 mm (±0.0002") | ||||

| Repeatability | ±0.003 mm (±0.00012") | ||||

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

010-3375-5684