다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

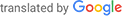

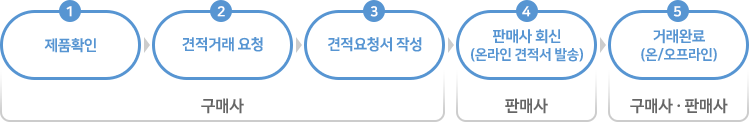

- 2. 견적 거래 절차 안내

AGMACHINE TECHNO CO

VERTICAL MACHINING CENTER 수직머시닝센터 VMC-137/VMC-168

견적거래 제품

대만 본사 직접 판매 '견적문의' 중국어/영어 문의 가능합니다.

- High-Stiffness Spindle Design

- Design of High Horse Power Spindle for Heavy-Duty Cutting

- X-Axis Chip Auger

- Three Chip Auger Design

- Belt-Driven Spindle

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

AGMA 제조사

문의전화 : 010-3375-5684 제조사 ‘AGMACHINE TECHNO CO’ 에서 직접 판매하는 제품입니다.

AGMACHINE TECHNO CO

VERTICAL MACHINING CENTER 수직머시닝센터 VMC-137/VMC-168

브랜드소개

제품정보

VMC-137/VMC-168

|

| The cartridge-type spindle enables it to reach 8,000, or 10,000 RPM using a belt drive assembly. Bearings at spindle nose end are well supported by a shaft sleeve and casting structure. The optimized bearing arrangement along with rigid spindle headstock reduces cutting-induced vibrations, virtually guaranteeing a better work piece surface finish. |

| The gear-driven cartridge spindle is capable of reaching speeds of 6,000 RPM. There is a dramatic increase in spindle rigidity due to increased spindle bearing support. This along with a high horsepower spindle motor dramatically enhances the machine's cutting performance. In addition, each gear-driven spindle has a spindle oil cooler used to lower bearing temperature and prolong spindle life. |

| The chip auger design provides optimal chip disposal and maximizes table cleanness. |

| Instead of using a costly chip conveyor, the special three chip auger system efficiently removes metal chips which produced during machining. |

| The spindle headstock has increased rigidity due to the wide stance design of the z-axis ways and the long surface contact between the headstock and way bars. |

| The two-speed gear transmission allows full power utilization. All gears are made of Chrome Molybdenum alloy steel, heat treated, and precisely ground to ensure the spindle runs quietly and smoothly. Furthermore, the design of the floating tool release mechanism minimizes any pressure exerted on the spindle bearings. |

| All three axes use ISO Class C3 precision ground preloaded ballscrews with pre-tensioned supports on both ends to minimize backlash and compensate the thermal induced error. |

| Four over-sized ways of the machine base combined with the large column helps make the structure a very rigid unit. The column is also heavily ribbed with honeycomb shape ribs to minimize any twisting caused during machining. When in operation, maximum contact surface between the spindle headstock and z-axis ways helps counteract heavy loads applied to the spindle structure. |

| The machine base of the VMC-168 uses a unique enclosed circular structure.This unique design allows the base to remain free of deformation that may occur due to the heat generated during machining. This unique design also allows the machine to remain stable after extensive usage. |

| Lubricating oil is evenly distributed to the sliding surfaces of the machine by using Showa oil distributors along with hard-plumbed, low maintenance oil lines. |

| This allows for rapid and efficient chip removal during machining in order to maintain a clean machine. |

| A high efficiency spindle cooling system dissipates running induced heat generation in order to maintain spindle accuracy and prolong spindle life. |

| Coolant through the spindle with pressure of 20-bar (280-psi) effectively reduces tool wear because of heat and the slow evacuation of metal chips. CTS with higher pressure is also available. |

| All of our machines are calibrated according to the "VDI 3441 3∂" standard. Calibration is performed for full travel length for each axis. Each measurement is taken six times to ensure the most consistent and accurate readings. |

| This unit offers larger tool capacity help to increase machining efficiency. The tool magazine is stored away from the working area to reduce any interference when the machine is in operation. |

| A rapid arm-type tool changer is driven with a precision cam, maintaining toolchanging accuracy of 0.01mm, which in turn will help maintain long-term spindle clamping accuracy. |

| All AGMA machines use a pressurized central lubricating system. The PLC controlled system allows all three axes to be lubricated evenly to maintain accuracy and prolong machine life. |

| Each machine goes through telescoping ball-bar tests to check contouring accuracy and uncover any geometric errors.This testing ensures the machine structure is both square and parallel. |

| The control panel swivels for easy use and also has a remote MPG for fast manual operations. |

| To ensure consistent high quality , each slide way is hand-scraped. Each axis saddle has Turcite material on it and a special "*" design is used along with a "Z" pattern for efficient oil through. There is an excellent distribution of oil to all axes, so setting time after rapid movements is eliminated, and stick-slip during cutting is minimized. |

| Model | VMC-137 | VMC-168 | |

| Spindle | Spindle Taper | NO.50 | |

| Transmission | Belt/Gear | ||

| Spindle Speed | 8,000/6,000 r.p.m. | ||

| Table | Table Size | 1,400mm x 710mm (55.12" x 27.95") | 1,700mm x 815mm (66.93" x 32.09") |

| T-Slot Size | 18mm x 6 x 125mm (0.71" x 6 x 4.92") | 18mm x 5 x 150mm (0.71" x 5 x 5.91") | |

| Work Area | 1,300mm x 700mm (51.18" x 27.56") | 1,500mm x 800mm (59.06" x 31.50") | |

| Max. Table Load | 1,600kgs (3,520lbs) | 2,000kgs (4,400lbs) | |

| Travel & Feedrate | X Axis | 1,300mm (51.18") | 1600mm (63.00") |

| Y Axis | 700mm (27.56") | 800mm (31.50") | |

| Z Axis | 650mm (25.59") | 700mm (27.56") | |

| Distance from Spindle Nose to Table | 200~850mm (7.87"~33.46") | 200~900mm (7.87"~35.43") | |

| Distance from Spindle Center to Column Ways | 755mm (29.72") | 855mm (33.66") | |

| Rapid Traverse | X, Y =15 M/Min (590IPM) Z=12 M/ Min (472IPM) | ||

| Cutting Feedrate | X, Y, Z: 1~10,000mm/min (393 IPM) | ||

| ATC | Tool Shank | BT/CAT-50 | |

| Pull Stud | MAS P50T-1(45º) | ||

| Magazine Capacity | 24 Tools | ||

| Max. Tool Diameter (with adjacent pocket empty) | Ø250mm(9.84") | ||

| Max. Tool Diameter (Full Storage) | Ø125mm(4.92") | ||

| Max. Tool Length | 300mm (11.81") | ||

| Max. Tool Weight | 15kgs (33lbs) | ||

| ATC Type | CAM Driven Arm Type | ||

| Motor | Spindle (Cont./30min.) | 18.5/22Kw (25/30 HP) Belt 15/18.5Kw (20/25 HP) Gear | |

| X/Y/Z Axes (Fanuc) | 4.0Kw (5.45 HP) | ||

| Lubrication Pump | 0.025Kw (0.033 HP) | ||

| Coolant Pump | 0.49Kw (0.66 HP) | ||

| Machine Height | 3,130mm (124") | 3,320mm (131") | |

| Floor Space | 3,600mm x 3,455mm (141.73" x 136") | 4,740mm x 3,298mm (186.61" x 129.85") | |

| Machine Weight | 12,000kgs (26,400 lbs) | 15,000kgs (33,000 lbs) | |

| Control | Fanuc 0iMF | ||

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

010-3375-5684