다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

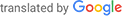

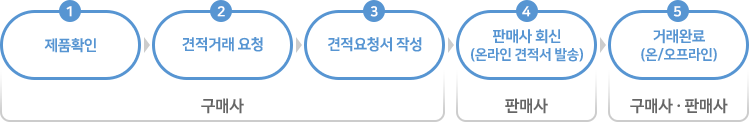

- 2. 견적 거래 절차 안내

㈜에사코리아

자기열교환형 버너 ENM-NXT

견적거래 제품

견적거래

- Walking beam furnaces.

- Walking earth furnaces.

- Frit melting furnaces.

- Pusher type furnaces.

- Aluminium smelting furnaces.

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

에사코리아 제조사

문의전화 : 0504-3175-2678 제조사 ‘㈜에사코리아’ 에서 직접 판매하는 제품입니다.

브랜드소개

제품정보

ENM-NXT 시리즈는 다양한 유형의 퍼니스에 사용하기위한 버너입니다.

버너용량과 사용 조건에 따라 ENM-NXT 버너는 600℃까지 예열 된 공기의 사용을위해 최적화 된 설계 덕분에 기존의 버너보다 오염 물질 배출 (CO 및 NOX)을 저감하고 기존 버너보다 낮은 소비를 보장합니다.

CHARACTERISTICS

GENERAL:

■ Capacity: from 400 to 4400 kW

■ Pre-heated air up to: 550°C

■ Air pressure to burner: 50 mbar

■ Gas pressure to burner: 50 mbar

■ Double combustion mode:

• FLAME with UV detection

• FLAMELESS for ULTRA LOW NOx emissions

■ Extremely low NOx e CO content

■ Large flow ratio (average of 6 : 1)

■ Maximum working temperature: 1600°C

MATERIAL COMPOSITIONS:

■ Burner body: carbon steel

■ Gas collector: cast iron G25

■ Air diffuser: refractory cement (T.max=1750°C)

■ Gas tube: AISI304/AISI310S

■ Body insulation: ceramic fibre

■ Surface treatment: galvanization, steel pickling,

high temperature painting.

CAPACITY PARAMETERS AND FLAME LENGTH

The ENM-NxT burner ignition takes place through PBCFR/

X series pilot burners. The detection instead, is done

via an UV-2 scanner (not supplied).

The adoption of flame control systems is highly recommended

for all operating plants that have temperatures

lower than 750°C (UNI EN746-2 regulations).

DESCRIPTION

The ENM-NxT burners are LOW NOx burners and the

most recent technical improvements have been applied

so as to guarantee low NOx and CO emissions, remaining,

however, functional even at low chamber temperatures,

during their ignition when the plant is cold.

The burners are solid and robust, with limited dimensions

and weight (the main insulation element is in ceramic

fibre), with separate air and gas inlets, nozzle mixing

(where flame backfire is impossible).

Multistage technology, together with the high combustive

gas recirculation, guarantees low NOx and CO emissions,

even with pre-heating temperature values of upto

600°C.

When it is necessary, the FLAMELESS version satisfies

the strictest standards, in terms of emissions, maintaining

however, the same air and gas feeding pressures as the

standard version.

BURNER PERFORMANCE

The capacities, flame lengths and velocities, refer to

a burner fed by natural gas (8600 Kcal/Nm3), placed in

a combustion chamber with zero pressure above sea

level and functional with 10% of excess air.

■ MIN/MAX functioning (ON/OFF)

■ Chamber temperature 1200°C

■ Pre-heated air temperature at 500°C

MAXIMUM CAPACITY

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

0504-3175-2678