다아라몰 견적거래 가이드

- 1. 견적거래란?

- 판매 제품에 대해 구매사와 판매사간 거래에 최적화되어 쉽고 편리하게 이용하실 수 있는 서비스입니다.

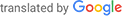

- 2. 견적 거래 절차 안내

㈜에사코리아

자기열교환형 버너 EMB-SIK-NXT

견적거래 제품

견적거래

- Tunnel or chariot furnaces.

- 최소 구매 수량 : 1

- 주문 수량 단위 : 1

에사코리아 제조사

문의전화 : 0504-3175-2678 제조사 ‘㈜에사코리아’ 에서 직접 판매하는 제품입니다.

브랜드소개

제품정보

EMB-SIK-NXT버너는 노즐 믹스 타입으로, 가스와 공기는 노즐 내부에서 혼합되는 구조로 화염의 역류를 방지합니다.

화염 튜브의 배출구 부분의 디자인으로 인해 모여진 2단계식 연소는 NOX, CO 양쪽 모두의 경우에 있어 낮은 양의 방출을 허용합니다.

EMB-SIK-DA are gas burners used in direct heating. The

shape of the silicon carbide flame tube produces a tight

flame which allows high heat penetration and better temperature

uniformity inside the combustion chamber due

to the high speed of the combustion products. Being able

to manage a secondary air inlet, these burners can be

used in low temperature applications where good tempetaure

uniformity is required. Furthermore, these burners

are particularly recommended for industrial furnaces

that must accomplish heat treament at different

temperatures.

APPLICATIONS

Fibre covered furnaces.

Tunnel or chariot furnaces.

Treatment furnaces.

Stretching furnaces.

Hot air generators.

Industrial drying.

CHARACTERISTICS

GENERAL:

Capacity: from 80 to 300 kW

Application maximum temperature: 1.300°C

Gas and air pressure to the burner: 45mbar

Flow ratio: 8 : 1

Flame speed: da 60 m/s a 120 m/s

Excess air: up to 400% without secondary air

up to 2000% with secondary air

MATERIAL COMPOSITION:

Burner body: cast iron G25

Gas collector: cast iron G25

Flame tube: SiC

Combustion head: AISI310

Fixing flange: Fe360

BURNER PERFORMANCE

The flame capacity, length and speed refer to natural

gas burners (8600 Kcal/Nm3), placed in a combustion

chamber at zero pressure at sea level and operating

with 10% excess air.

MIN/MAX (ON/OFF) functioning

Chamber temperature1000°C

Ambient air temperature

NOx < 180 mg/Nm3 [O2 = 3% ref.]

INSTALLATION

The EMB-SIK-DA burners have appropriate furnace wall

fixingflange. The light obtained for the burner housing

must leave open space around the burner. This space

has then to be filled with ceramic-fibre.

For the installation carefully follow the instructions below:

1 - Place the EMB-SIK-DA burners far from heat sources

and productssuch as: liquids, solvents or corrosive gases.

2 - Make sure that the housing dimensions and the distance

between the centers of the feeding pipes correspond

to what is specified in the "Overall dimensions" chapter.

3 - Assemble the burner onto the furnace wall (pos. 01)

interposing a ceramic fibre gasket between the attachment

flange and the furnace wall (pos.08). During the

burner insertion phase check that the insulation previously

wrapped around the outside is not altered nor damaged.

Once the spacer has been fixed onto the furnace,

from the inside of the combustion chamber, seal any possible

cracks that may be left between the wall and the

spacer with ceramic fibre.

4 - Connect the combustion air and fuel gas inlet piping,

interposing, if possible, dilation joints of correct sizes.

5 - Connect electricity to the ignition electrode and to the

uv-scan detector making sure not to pass the conductors

near heat sources..

6 - Check that the burner body and all its metallic elements

are earthed with appropriate conductors.

7 - The connecting cable from the ignition transformer to

the electrode must be specific for high tension and not

screened. It must not be more than 1 metre long; otherwise

the ignition transformer must be positioned near the

burner. The high tension cable must be placed far from the

power cables and not in metallic ducts. Ideally it should be

left in open air.

8 - For further information please consult the technical

data sheet concerning the ignition transformers.

월 ~ 금요일 오전 9시 ~ 오후 6시 까지

0504-3175-2678